Magnesite board is a good and versatile choice for construction work

Magnesite board «MAGNECO» is a building and finishing material with a unique set of positive operational performance, which provides the material with the widest range of applications.

Magnesite board «MAGNECO» is a building and finishing material with a unique set of positive operational performance, which provides the material with the widest range of applications.

The use of a magnesite board «MAGNECO», due to its physical and mechanical characteristics, in most cases, is more reasonable than the use of well-known construction and finishing materials such as gypsum board (including water-resistant and heat-resistant), any material on the basis of gypsum, plywood, Aquapanel, various board materials such as wood chipboard, QSB, OSB, asbestos cement shingle, fiber cement boards, etc. Under the same operating conditions, in comparison with a magnesite board, any other known construction material would not give you the desired result.

During the production of magnesite board «MAGNECO» it is used only natural components in the complete absence of any extraneous additives and impurities, which makes this material the absolute leader in the environmental issue.

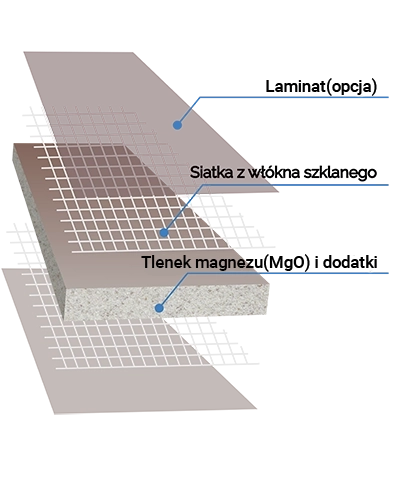

Composition of magnesite board «MAGNECO».

Magnesite board «MAGNECO» in its composition is as follows:

- the main components of magnesite board are chloride and magnesium oxide, the reciprocal reaction of which creates a very strong crystal lattice. This strong structure serves as a container for fixing of various kinds of fillers;

- volcanic sand, the other name – perlite, which reduces both the thermal conductivity of magnesite board, and its weight, thus increases the performance parameters for sound insulation;

- fine fraction sawdust add the volume and lightness to magnesite board;

- basalt fiberglass is used for bilateral reinforcement of magnesite board. This component allows to make the board flexible and robust.

Due to such complex of components and developed, by specialist of our company, production technology, magnesite board gets high consumer quality directly on the production line, without the use of third modification agents, various types of surface treatments, etc.

A high percentage of magnesia cement in magnesite board «MAGNECO» produced by Company Magnesite Poland, makes this product the absolute leader in the market of construction and finishing materials based on magnesia binders.